Gaskets for Plate Heat Exchangers

|

We supply replacement gaskets from the most commonly found to rarely found gaskets. All of our gaskets are made directly at our factory in India using only the best quality raw materials.

Syntholine Plate heat exchanger gaskets are manufactured in accordance with a rigorous quality control procedure. With our gasket testing facilities, we are able to fully inspect gaskets to ensure they continuously meet our high standards. The heat exchanger gaskets are fixed to the heat transfer plates either mechanically or with an adhesive. The common attachments are listed below. We are constantly increasing our range of PHE gaskets, with the rapid evolution in the design of heat exchanger plates, and new models being introduced. For more detailed information please contact us. Materials:Nitrile, HNBR, Butyl, EPDM, Neoprene, Viton (TM) and more

PHE Gaskets are produced in Industrial and Food Grade materials for the above elastomers. All food grade gaskets are manufactured as per FDA CFR 177.2600. |

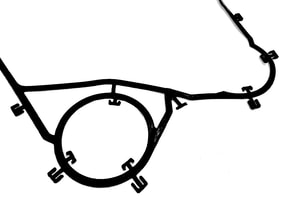

Type of Attachments

Adhesive Attachment - Glue type PHE Gaskets

With adhesive attachments a "glue" is used to bond the heat exchanger gaskets to the heat transfer plates. The adhesive does not contribute to sealing the heat exchanger it is merely used to hold the gasket in place while the heat exchanger is tightened - it is the tightening down of the heat exchanger which compresses the plate/gaskets and creates the seal.

Mechanical Attachments - Stud, Clip and Snap-in types

Most modern plate heat exchangers use a form of mechanical attachment to fix the gaskets to the heat transfer plates.

With adhesive attachments a "glue" is used to bond the heat exchanger gaskets to the heat transfer plates. The adhesive does not contribute to sealing the heat exchanger it is merely used to hold the gasket in place while the heat exchanger is tightened - it is the tightening down of the heat exchanger which compresses the plate/gaskets and creates the seal.

- Pros. The gaskets remain attached to plates when being cleaned on site. i.e. when using a high pressure washer.

- Cons. When replacing gaskets the heat transfer plates require off site servicing to ensure the gasket grooves are clean and the new gaskets are bonded correctly.

Mechanical Attachments - Stud, Clip and Snap-in types

Most modern plate heat exchangers use a form of mechanical attachment to fix the gaskets to the heat transfer plates.

- Pros. The gaskets can be easily removed and replaced, especially on site, as the gasket sealing area remains clean (free from glue residue).

- Cons. The gaskets will become detached from the heat transfer plates when pressure washing on site or through incorrect / rough handling. Care must be taken when tightening the heat exchanger to ensure the gaskets remain in the gasket groove - occassional checks should be made whilst tightening down so any gaskets that have moved out of the groove can be pushed back in.